technologies

research and development

Searching for innovative ideas, developing new materials as well as creating innovative products is the main task of the Technological Department and the Research and Development (R&D) Department. In our five business units, we manufacture and constantly develop our products, at the same time fulfilling changing requirements of our customers.

more

CAST film extrusion

Breathable film production is an advanced CAST extrusion process. One of the main components is a specially selected calcium carbonate, which in large volumes, gives the film a “silky” feel and enables it to transmit vapours, creating so-called “breathability”.

more

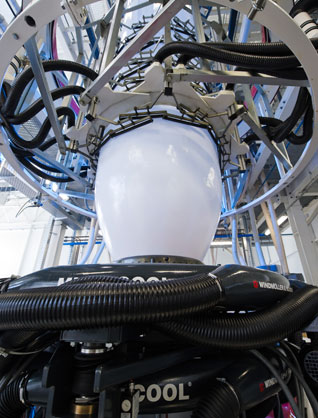

BLOWN film extrusion

In the process of BLOWN film extrusion, polyethylene granulates are processed into a plastic tube, which is manufactured with the usage of an extrusion die. The die is constructed in such a way that a film balloon occurs during production; the air of a detailed temperature is insufflated into it, which enables cooling the film and giving it unique physico-mechanical properties.

more

film perforation

In the perforation process, melted plastic materials are sucked through a perforating screen, which results in the film having a three-dimensional structure.

more

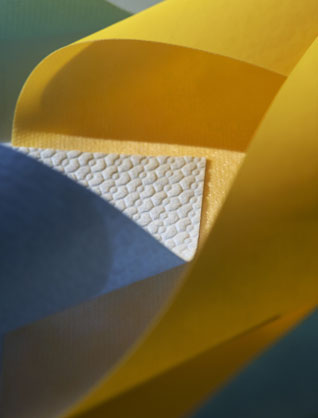

HOT-MELT lamination

The lamination is a process of joining two or more layers of various materials together: non-woven fabrics, films, tissues, air-laid, viscose, paper, PUR foam and others. The thickness of raw materials can range from several microns to a few millimeters and maximum web width of 2500mm. Our company offers also multilayer laminates.

more

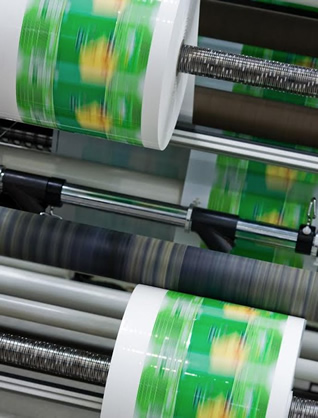

FLEXO printing

The production lines are equipped with the most modern technological solutions such as EASY SET or EASY REG, which enable setting the printing process with minimum material consumption. The printing process is controlled by the surveillance system consisting of 3 video cameras that guarantee 100% quality.

more

LASER-FILTER recycling

Each year we observe continuous increase in the amount of plastic waste that comes from various industries and economies. In most cases it ends up in the landfill site but due to the long period of the degradation it is disadvantageous to keep it in there. The hope for improvement of this situation is the plastic waste recycling. It will bring the economic and ecological benefits.

more

flexible packaging

The attractiveness and functionality of a packaging are the properties, whose combination is equal to producer’s success and customer’s satisfaction. In Plastica Ltd., each single packaging is individually designed for the needs of a finished product.

more

medical packaging

Safe medical packaging BOM are dedicated for sterilization of medical devices by steam, ethylene oxide, formaldehyde, radiation or plasma based on hydrogen peroxide. Individual approach to each way of sterilization provides optimal technical solutions.

more

EO sterilization

Ethylene oxide sterilization is a technological process in which medical devices packed in cardboard boxes are exposed to S-90 gas. The sterilization process is designed on the basis of a detailed medical device analysis; the crucial factors are among others the type of materials and their absorptivity and porosity.

more

steam sterilization

Thermal sterilization in overpressure with usage of water vapour is the safest sterilization method of medical products. The sterilization saturated by water vapour is a universal, certain, fast, non-toxic and what is very significant economical process. When choosing this method of sterilization it is very important to remember that the decisive factor in determining its effectiveness is high temperature therefore the product that is subjected to the process must be thermostable.

more

ADR technology

Water is a fundamental element of the environment and ecosystem that we live in. Without water the creation of life would not be possible. Water is present in all tissues of our body however it is not distributed evenly. It is indispensable to keep biological and cellular processes, it is involved in food ingestion process, takes part in cells nutrition and provide them essential energy.

morePolimery

Plastica Sp. z o.o. wspiera akcję społeczną POLIMERY PRZYJAZNE CZŁOWIEKOWI, POTRZEBNE LUDZIOM

Niewiele jest spraw, co do których Polacy są zgodni. Jedną z nich jest fatalny publiczny wizerunek tworzyw sztucznych. Przemysł tworzyw stał się dyżurnym „chłopcem do bicia” w Polsce i UE, jest obwiniany za wszelkie błędy i wypaczenia naszej cywilizacji. Czas na podjęcie działań, które w rozsądnej perspektywie pozwolą zmienić negatywne społeczne nastawienie wobec tworzyw.

Przede wszystkim najwyższy czas na wyrugowanie z przestrzeni publicznej koszmarka językowego „tworzywa sztuczne”. Ten termin natychmiast odrzuca każdego normalnego człowieka, jego ocieplenie i zmiana wizerunku na pozytywny wydaje się niemożliwa, albowiem nic co „sztuczne” nie może być przyjazne człowiekowi. Dlatego proponujemy zastąpienie koszmarka językowego terminem „tworzywa polimerowe”, a szerzej POLIMERY. Nazwa POLIMERY oddaje istotę rzeczy i nie jest obciążona negatywnymi asocjacjami i skojarzeniami wytworzonymi wokół koszmarka językowego. Jest nawet sympatyczna i, jak widać po logo akcji, da się za jej pomocą komunikować treści mające odzwierciedlenie w rzeczywistości.

Pamiętajmy, że jak mówi Pismo, na początku było Słowo. Język ma kluczowe znaczeniu w międzyludzkiej komunikacji i tworzeniu korzystnego lub negatywnego wizerunku. Krótko mówiąc: język tworzy rzeczywistość.

Celem akcji jest rozpropagowanie terminu POLIMERY, który w niedalekiej przyszłości powinien zastąpić koszmarek językowy. Przemysł polimerowy musi się zacząć w końcu bronić. Polimery są niezbywalnym elementem naszej cywilizacji i tylko od człowieka, od nas samych zależy, jak będą nam służyć.

Wprowadzenie terminu POLIMERY do dyskursu publicznego pozwoli rozpocząć wiele pozytywnych działań wizerunkowych we współpracy z mediami i organizacjami społecznymi.

Zmiana wizerunku branży powinna ożywczo wpłynąć na sam biznes. Zejście z linii strzału ekologów, mediów, polityków, innych grup opiniotwórczych, powinno przynieść mierzalne biznesowe efekty. Taki stan rzeczy na pewno zostanie zauważony przez inwestorów zagranicznych. Wreszcie, może to być sygnał do konsolidacji przemysłu polimerowego, co zaowocuje wzrostem siły i znaczenia tej branży w całej gospodarce.